Hydraulic Seals Pu Seal

In the temperature range of -65F to +200F, Polyurethane hydraulic seals are usually the most economical and best design choice.

In addition to being inexpensive, polyurethane is also tough, wear-resistant, and can withstand impact loads better than most elastomers.

We provide hydraulic seal Pu Seals in st5d imperial and metric sizes, as well as customized contours and configurations of polyurethane washers and Polyurethane hydraulic seals customized to your specifications.

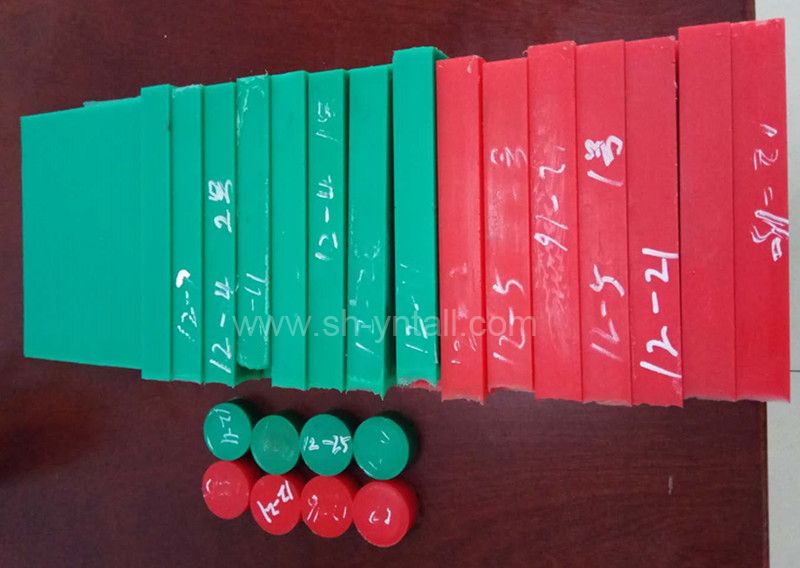

We can provide polyurethane O-rings, gaskets and seals with standard hardness of 70 or 90, and provide customized hardness to meet your needs. There are also many colors to choose from.

Characters:

PTMEG-MDI based PU (polyurethane) seal, good physical properties, good abrasion resistance, good hydrolysis resistance, good for after treating processing ability, low compression set, and good dynamic property. Our products are of stable quality.

Applications:

Seals can be used for tractors and excavator.

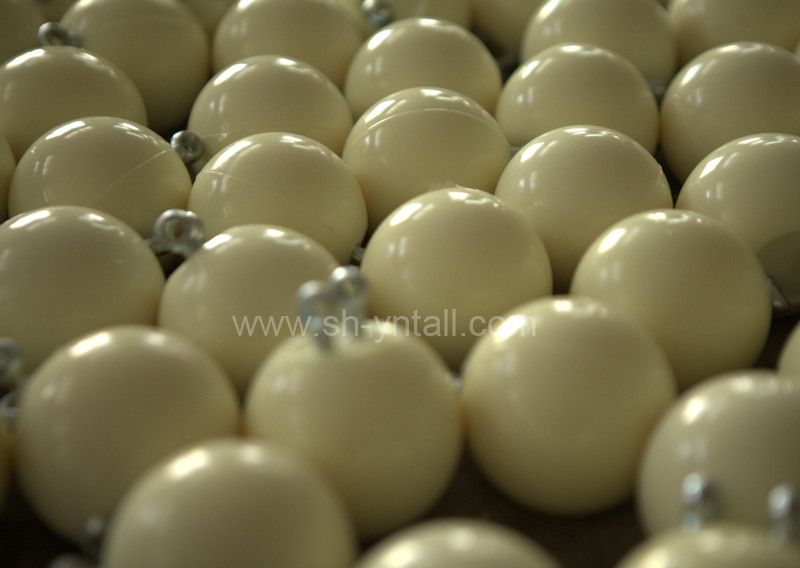

Casting Polyurethane (CPU) is a kind of polyurethane elastomer which is produced by casting process, liquid components are cast into the mold and reacted to get the final part.

Pu Seals advantages:

Wide range of hardness (Shore 0A-85D)

Wear and abrasion resistance

pu seals are scratch-resistant

Pleasant feel / soft touch surface

Fastness to light for aliphatics (non-yellowing)

Elasticity / Flexibility

High resistance against oils and greases

Flexibility at low temperature

Low cost for processing

Particularly strong wear resistance

Insensitivity to shock loads and pressure peaks

High crush resistance

It has an ideal sealing effect under no load and low-temperature conditions

Suitable for demanding working conditions

pu seals Easy to install

For PU seals:

Common raw Material: PTMEG+MDI based

Existing molds: 500+

Making molds inhouse

Dimension: 0-650*750mm*150mm

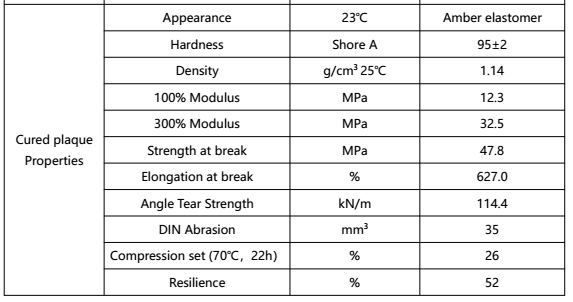

Enterprise standard No. : Seal 1607

Standard test seal: 150*195

Plaque of every casting batch

Measuring by sight for seal: surface, flow mark,,,